Installing Maretron NMEA 2000 connector on bulk Maretron Mid (Blue) Cable

Posted on Tue 10 August 2010

Here’s a quick step by step on how to use the Maretron field installable connectors. These are useful when you want to run a wire in a mast or through the deck and you don’t want to use a bulkhead fitting but you’d rather use something like a Blue Sea cable clam. There are NO instructions with these fittings so I hope you find this useful.

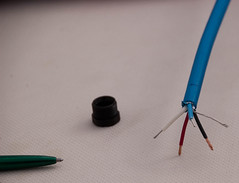

Here’s a shot of the disassembled connector and the raw end of the bulk wire. The white fitting and it’s rubber gasket give this fitting a snug water resistant (proof?) fit.

This is a shot of the little tiny holes and screws you’re going to be using to attach the wires to the connector. Everything it very well designed; the color coding makes this a snap. Note that the blue connection is stands approximately 1/4” proud of the other fittings.

You need to strip back the outer insulation and the foil around the wires. The blue wire should be a bit shorter than the others since it doesn’t have to reach as far as the other wires.

Here’s a shot with all of the wires attached to the connector.

Notice in the that previous picture none of these other pieces are visible. they all need to be placed on the wire BEFORE you spend 10 minutes getting the wires attached and all the screws tightened. If you’re lucky and you don’t have a connector on the other end, you can slide them all the way along the wire like I did. DOH!

I started by tightening the body to the very end of the connector (the left side in this pic). I then worked on the final end fitting where the wire extends out. When you got to tighten everything up it will be a tad difficult to get the end fitting to tighten against the white cone and rubber bushing. I used the small screw driver to work the cone down as far as a I could. be careful, you can break the cone if you push too hard. You will figure it out though. I then used a Knipex Pliers Wrenches (which I LOVE but a crescent wrench would work) to hold the connector body while I bottomed all of the threads.

It’s obviously a lot easier to work with the factory installed connectors but where necessary the field installable connectors are pretty easy to work with and they look solid to me.