I love to update the blog with checkboxes as we go. Feels good to

celebrate the wins and document our progress. As you know we’re working

toward stepping our masts on Thursday 24 June.

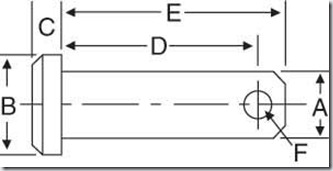

I got all the pins from Andersen Machine Shop in Port Townsend and they

were beautiful. Had a slight mishap with them last week because I put in

an incorrect dimension (too long) for some of the pins, but with PT all

mail is basically overnight so we were able to send them back have them

cut down and get them back in 2 days! I highly recommend Andersen

Machine Shop. Olaf is a very nice guy and was very helpful. He made our

pins on his CNC machine, they look awesome. With pins in hand I was

able to attach all of the rigging to the masts! I did all that in the

pouring “Junary” rain we’re experiencing in Seattle this summer so no

pics yet.

On the boat Dawn has been working on the ash battens to line the aft

berth, v-berth and open lockers.

First she’s lining all our lockers with Reflectix Insulation

which looks like aluminum foil bubble wrap. We’re laying it in loose along the

hull NOT gluing it down. We don’t ever want to have to

scrape the hull for a month again.

The insulation will keep a tad warmer here in Seattle and a tad cooler in the

Tropics. It’s pretty cheap, you can get it at Home Depot and its easy to work

with.

Here’s what the battens look like when they are installed. Dawn as always does

gorgeous work when I stay out of the way. ;-)

The only thing left to do before we step the masts on Thursday are to

install the mast steps and make some leather grommets for the wiring

exits on the main mast. After that I’ll remount the booms and winches

along with a couple other things. Right after we tune the rig we should

be able to sail again!