I am in Port Townsend this weekend attending the Brion Toss Rigging

Workshop. At the end of day one, its been very worthwhile thus far. The basic

flow of the class thus far has been to walk through the systems of a rig,

explain what they are, how to think about them in terms of the entire rig,

how to inspect them, etc. Obviously the point isn’t to make you an expert in

2 days, but I’m feeling like at the end of this I’ll be a much better informed

consumer when we do our re-rig and I think there are aspects of it I could do

myself in consultation with someone who is a rigger by profession.

I am in Port Townsend this weekend attending the Brion Toss Rigging

Workshop. At the end of day one, its been very worthwhile thus far. The basic

flow of the class thus far has been to walk through the systems of a rig,

explain what they are, how to think about them in terms of the entire rig,

how to inspect them, etc. Obviously the point isn’t to make you an expert in

2 days, but I’m feeling like at the end of this I’ll be a much better informed

consumer when we do our re-rig and I think there are aspects of it I could do

myself in consultation with someone who is a rigger by profession.

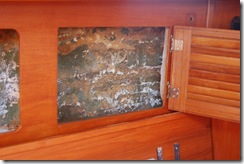

In addition to the classroom there has some hands-on and dock-walking.

Its one thing to talk about chain plates, clevis pins, wire and fair

leads and then to go look at an actual boat. The hands on activities,

drilling a hole in a spar (I never got my entry and exit holes to

line-up), knot tying for going up the mast, and splicing an eye into

three-strand braid were great. The splicing part was particularly

awesome because it took something that I thought was witchcraft and

proved to me that I could definitely learn do it and it.

As a rock climber I found some of the knots and practices used in going

aloft to be a little riskier than what I am used to and the terminology

to be confusing but that’s fine and I’ll probably adapt some of my

climbing into my own practices. For instance they will hoist a

ratcheting block to allow the person going aloft to raise themselves

(using a another halyard as a backup) and using a carabiner hitch to

tie-off when at the top. I think I’d rather have a something like a

Gris-gris

instead, but Brion did mention that could also be an option when were

out on the dock so its not like the two are odds with each other. Also

people climbed using two carabiners as a belay device for a long time

before any specialized devices were made so really for me I think its

just a comfort thing for me to use what I’m used to (i.e., they are

right too).

We ended the day talking about wire sizes and how to calculate what you

need on your boat for shrouds, stays as well as how to calculate

chainplate dimensions. That was really interesting and the formulas are

pretty simple. I’ll try to work up all the numbers for a Pearson 424

tonight as I’m reviewing my notes.

Its been a great first day and I’m looking forward to tomorrow. I’m off

to roam Port Townsend for awhile before dinner.

[gpress map_position="48.11749711017371, -122.75229328459473"

marker_title="My Map" map_type="SATELLITE" map_zoom="13"]

by Don Casey.

by Don Casey.